Development and optimization of microbial lignocellulose-based fermentation processes for the production of bulk chemicals and fuels

Steadily rising oil prices, shortage of oil resources and the negative impact of its use on the environment evoke an increasing scientific, political and industrial interest in developing safe and efficient processes for producing fuel and chemicals from renewable resources. Novel industrial fermentation processes are preferentially based on non-food substrates such as lignocellulose and combine the advantages of aerobic and anaerobic conditions within a single reactor; i.e. rapid aerobic biomass formation with high cell densities and subsequent anaerobic high yield and zero growth production (dual phase). This strategy should result in efficient processes with high overall yield and productivity.

Towards these goals

- We identified 16 chromosomal integration sites in which genes relevant for the consumption of D-xylose and L-arabinose were integrated. The engineered strains showed high growth rates on a hemicellulose fraction from an Organosolv approach. Finally, we developed an isobutanol fermentation process on this fraction using a tailor-made C. glutamicum strain.

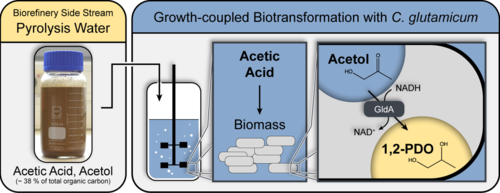

- Pyrolysis water is a previously unused stream of rapid pyrolysis of straw. Using specially engineered C. glutamicum strains, we developed a two-phase fed-batch process with pyrolysis water as substrate in which 1,2-propanediol was produced with high yield and high productivity.

- In another task we provide a deep insight into the transient transcriptional adaptation of C. glutamicum to an increasing oxygen limitation during a dual-phase process.

| Project title | Development and optimization of microbial lignocellulose-based fermentation processes for the production of bulk chemicals and fuels |

| Institution | University of Stuttgart, Institute of Biochemical Engineering |

| Research group | Prof. Dr. Bastian Blombach, Dr. Julian Lange |

| Status | completed |