Fractionation and modification of lignin

The overall objective of this project is to produce lignin-based polyfunctionated building blocks for the development of chemical products (resins, paints, adhesives).

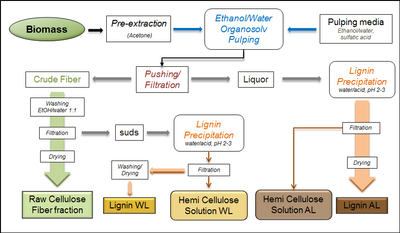

Lignin is extracted from grass (Miscanthus) or hardwood (Poplar) using an organosolv-pulping-process, which needs to be adjusted and optimized for each biomass source. Three main fractions are generated (cellulose, hemicellulose, lignin) during the pulping process. The derived "organosolv-lignin" as well as "Kraft-lignin" is analytically characterized and afterwards separated by thermal fractionation methods into high and low molecular weight fractions. The resulting lignin-based building blocks are then again characterized by analytical methods and may be chemically modified.

For chemical functionalization hydroxyalkylation and the synthesis of dihydroxy-alkyl-aryl-ethers are being used. Based on results from chemical analyses, possible applications are finally defined.

Due to the above mentioned choice of grass and hardwood lignocelluloses combined with various pulping- and fractionation-methods, lignin and lignin fractions with different structures and properties will be produced. The assignment of material properties to certain process parameters will ensure high adaptability for raw materials, processes, and products during the development of lignocellulose-based value chains. Chemical modification of the fractions will also enable variability in their chemical functionalities and an expansion in material applications.

| Project title | Optimization of an Organosolv-Pulping-Process: grass and hardwood/fractionation of lignin and generation of polyfunctionated intermediates |

| Institution | Fraunhofer Institute for Chemical Technology (ICT) |

| Research group | Dr. Detlef Schmiedl, Dr. Beatrice Tübke, Sarah Böringer, Viktoria Rohde |