Biotechnological production of platform chemicals using anodes-assisted fermentation

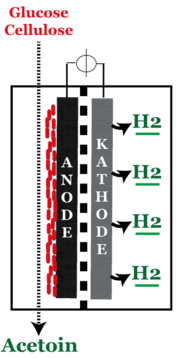

The aim of this project was the biotechnological production of platform chemicals by means of an anode-assisted fermentation. A number of platform chemicals are more oxidized than typical substrates for biotechnological processes. Their production therefore requires the addition of an electron acceptor. Normally, oxygen is used for this purpose. Respiration with oxygen is typically associated with a high energy gain for the microbial biocatalysts. This is manifested by a strongly anabolic utilization of the added substrate and by heat generation in the reactor. In the process presented here, the electrode of a bioelectrochemical system should alternatively be used as an electron acceptor. Thus, it is possible to perform oxidative conversions even under anoxic conditions. In this project, a biocatalyst and a model for an anode-assisted process should be developed. Based on these results, a model reactor was to be constructed. We were able to work out molecular mechanisms that can be used to achieve robust biofilm growth on anodes. Using these molecular modifications, we were able to increase the current density by a factor of 4 compared to the wild type. We were then able to further realize a 5-fold increase by adjusting the medium. We were able to develop a robust model of anode-assisted fermentation. This model will be the basis of the process engineering design of the process. In addition, we aim to have our processes automatically optimized online based on artificial intelligence as a goal of further work. The developed model will be the basis for the algorithms on which the artificial intelligence will be based. We were able to develop a resilient and scalable reactor concept. We want to use this concept with partners from industry for the integration of bioelectrochemical processes into the market.

| Project title | Biotechnological production of platform chemicals using anodes-assisted fermentation |

| Institutions and researcher | Karlsruhe Institute of Technologie, Applied Biology Engler-Bunte-Institute at KIT |