Process and system analysis of power-to-gas concepts

Despite increasing the electrification of the energy system, large amounts of chemical energy sources will be needed as a medium and long-term storage solution in order to achieve the federal climate goals.

Therefore, the project focused on the definition and evaluation of concepts for the coupling of existing biogas plants with biological methanation (BM) based power-to-gas plants. In the case of BM, microorganisms convert the hydrogen, which is produced by electrolysis, and carbon dioxide to methane. The advantage of this approach is that the carbon dioxide produced in the biogas production process can be almost completely converted to methane. This increases the carbon conversion in the plant and maximizes the renewable gas output, which then can be stored in the existing natural gas infrastructure.

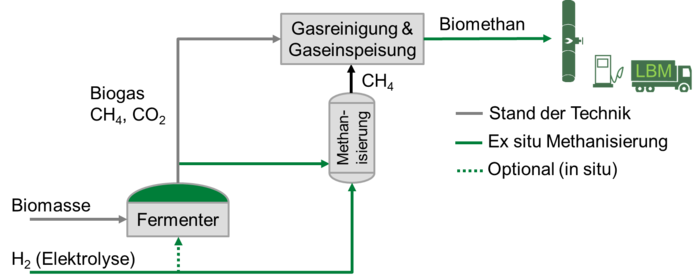

Figure 1 shows the two general options for integrating the BM: a) into conventional fermenter systems (in situ) or b) into a separate reactor (ex situ). The methane formation rate (MFR) is limited in both options due to the slow mass transport of hydrogen through the liquid phase to the microorganisms. The modeling of BM reactors, which was carried out in the project, shows that in-situ methanation requires a minimum height of fermenters, which is very often not given in existing plants. For the ex situ methanation based on trickle bed reactors, different concepts were investigated on a theoretical basis in the project and optimization potentials for increasing the MFR were given.

The technical analysis of the entire PtG chain, starting with the provision of electricity, shows a maximum efficiency of 69% assuming the best possible heat integration. The SNG production costs for ex situ plants amount to 9 - 11 ct / kWh (Hi, CH4, electricity costs = 3 ct / kWh, full load hours of electrolysis = 4,000 FLH). Even lower production costs of approx. 8 – 9 ct / kWh (Hi, CH4) are possible, in case ex situ reactors are coupled with existing biogas plants. This option may be of interest to plant operators whose BGAs can no longer obtain EEG support in a few years.

For Baden-Württemberg, the analyses show a future biomethane production potential of 10 - 17 TWh / a. Depending on the underlying study, this potential corresponds to a coverage of 20% to 50% of Baden-Württemberg's gas demand in 2050. The technologies and process chains analyzed in the context of the project can make a significant contribution to achieving Germany's climate goals in the future.

| Project title | Process and system analysis of Power-to-Gas concepts |

| Institution | DVGW-Research program at Engler-Bunte-Institut of Karlsruher Institute of Technology |

| Research group | Dr.-Ing. Frank Graf, Friedemann Mörs, Katharina Bär |

| project status | completed |